Contingency Management:

Overview

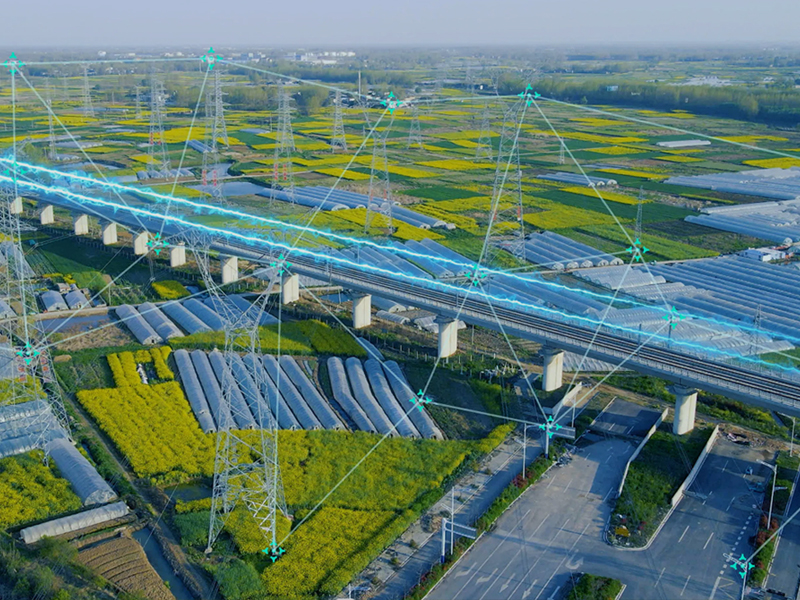

The robot improves the stability of the whole system by improving the anti-interference ability of its own components and shielding the external electromagnetic interference.

System functions

-

Automatic identification and temperature measurement of rollers

-

Belt tear monitoring

-

Belt deviation monitoring

-

Coal leakage monitoring

-

Foreign object monitoring

-

Fire monitoring

-

Environmental monitoring

-

Area intrusion monitoring

-

Personnel behavior monitoring

System advantages

- Dynamic and efficient inspection

- Automatic identification and temperature measurement of rollers

- High flexibility folding arm

- Support offline running

- Support edge computing

- Strong environmental adaptability

- Long-term stable operation

System introduction

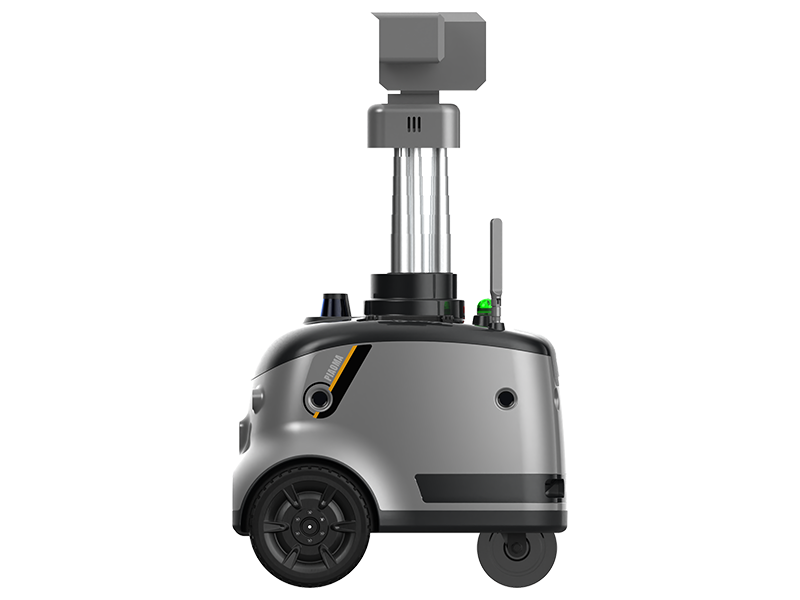

The system is composed of PMR-T1A belt conveyor rail hanging inspection robot and PMR-A1A belt tear detection system. By inspecting the coal conveying process, the risks in the conveying process can be found in time.

PMR-T1A rail inspection robot for belt conveyor