Power station:

Overview

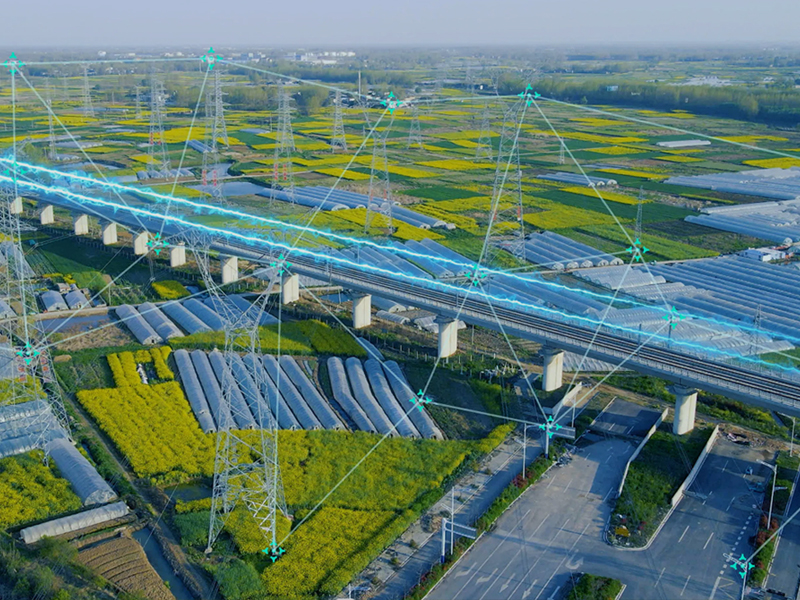

Inside the coal conveying trestle of the power plant, the concentration of coal dust is large, the environment is dim, the arrangement of equipment is complicated, the passage area is narrow, the accumulation of dust is serious, the noise is loud, and the working environment is relatively harsh. At the same time, the inspection items are many and varied, and it is difficult to rely only on personnel or fixed cameras to carry out safety inspections to detect potential safety risks in a comprehensive and timely manner.

System functions

-

Automatic identification and temperature measurement of rollers

-

Belt tear monitoring

-

Belt deviation monitoring

-

Coal leakage monitoring

-

Foreign object monitoring

-

Fire monitoring

-

Environmental monitoring

-

Area intrusion monitoring

-

Personnel behavior monitoring

System advantages

- Dynamic and efficient inspection

- Automatic identification and temperature measurement of rollers

- High flexibility folding arm

- Support offline running

- Support edge computing

- Strong environmental adaptability

- Long-term stable operation

System introduction

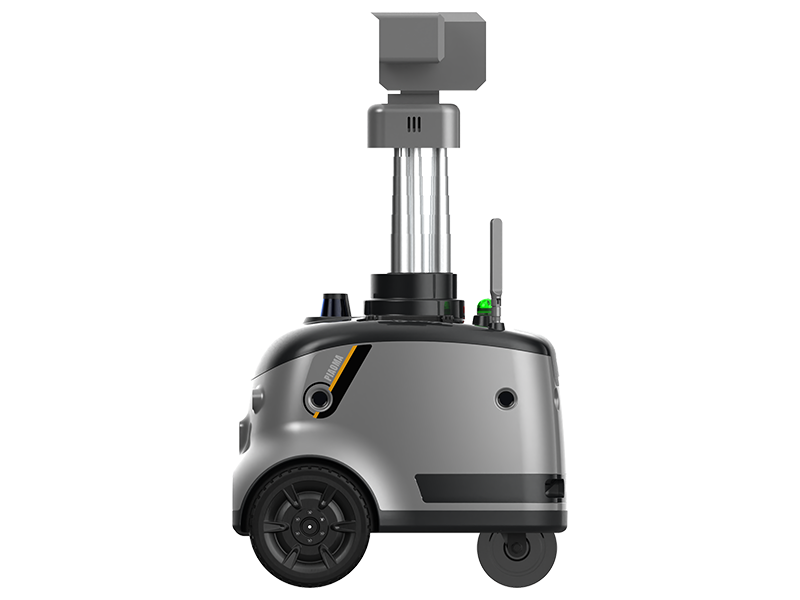

The system is composed of PMR-T1A belt conveyor rail hanging inspection robot and PMR-A1A belt tear detection system. By inspecting the coal conveying process, the risks in the conveying process can be found in time.

PMR-T1A for belt conveyor rail inspection robot